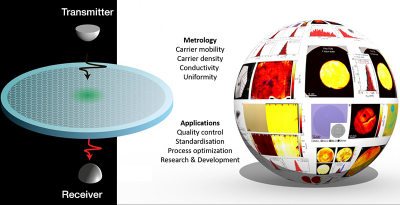

Terahertz spectroscopy penetrates graphene films allowing scientists to make detailed maps of their electrical quality, without damaging or contaminating the material. The Graphene Flagship brought together researchers from academia and industry to develop and mature this analytical technique, and now a novel measurement tool for graphene characterisation is ready.

The effort was possible thanks to the collaborative environment enabled by the Graphene Flagship European consortium, with participation by scientists from Graphene Flagship partners DTU, Denmark, IIT, Italy, Aalto University, Finland, AIXTRON, UK, imec, Belgium, Graphenea, Spain, Warsaw University, Poland, and Thales R&T, France, as well as collaborators in China, Korea and the US.

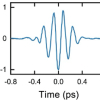

Graphene is often “sandwiched” between many different layers and materials to be used in electronic and photonic devices. This complicates the process of quality assessment. Terahertz spectroscopy makes things easier. It images the encapsulated materials and reveals the quality of the graphene underneath, exposing imperfections at critical points in the fabrication process. It is a fast, non-destructive technology that probes the electrical properties of graphene and layered materials, with no need for direct contact.

The development of characterisation techniques like terahertz spectroscopy is fundamental to accelerating large-scale production, as they guarantee that graphene-enabled devices are made consistently and predictably, without flaws. Thanks to other developments pioneered by the Graphene Flagship, such as roll-to-roll production of graphene and layered materials, fabrication technology is ready to take the next step. Terahertz spectroscopy allows us to ramp up graphene production without losing sight of the quality.

“This is the technique we needed to match the high-throughput production levels enabled by the Graphene Flagship”, explains Peter Bøggild from Graphene Flagship partner DTU. “We are confident that terahertz spectroscopy in graphene manufacturing will become as routine as X-ray scans in hospitals”, he adds. “In fact, thanks to terahertz spectroscopy you can easily map even meter-scale graphene samples without touching them, which is not possible with some other state-of-the-art techniques.” Furthermore, the Graphene Flagship is currently studying how to apply terahertz spectroscopy directly into roll-to-roll graphene production lines, and speed up the imaging.

Setting standards is an important step for the development of any new material, to ensure it is safe, genuine and will offer a performance that is both reliable and consistent. That is why the Graphene Flagship has a dedicated work-group focused on the standardisation of graphene, measurement and analytical techniques and manufacturing processes. The newly developed method for terahertz spectroscopy is on track to become a standard technical specification, thanks to the work of the Graphene Flagship Standardisation Committee. “This will undoubtedly accelerate the uptake of this new technology, as it will outline how analysis and comparison of graphene samples can be done in a reproducible way”, explains Peter Jepsen from Graphene Flagship Partner DTU, who co-authors the study. “Terahertz spectroscopy is yet another step to increase the trust in graphene-enabled products”, he concludes.